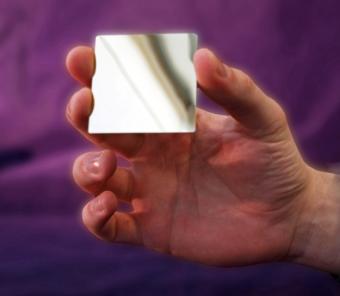

Optical Solar Reflectors

Excelitas is a world leading manufacturer of radiation stable Optical Solar Reflectors for the space industry. An optical solar reflector (OSR) is used for the thermal control of spacecraft on the sun-facing sides of satellites by reflecting incoming solar radiation while simultaneously radiating internally-generated heat. Our OSRs are used in most major satellite programs for both civilian and military applications in Europe, USA and Japan

We are a highly specialized manufacturer of radiation stable micro-sheet coverglass with extensive on-orbit proven performance. With dedicated glass melting based in our UK operations and unique patented glass formulations, we offer a fully integrated high-volume manufacturing capability to meet your most challenging qualified-space glass requirements. Our advanced research and development continue to keep us on the leading edge of space technology.

We entered the space business in 1970 as Pilkington Space Technology. Our unique range of cerium-doped micro-sheet has been utilized on over 3000 satellites in LEO, MEO, GEO and beyond.

Glass Options

- CMX

- CMG

- CMO

Coating Options

- Single layer Anti-reflection coatings

- 多层Anti-reflection coatings

- Conductive Anti-reflection coatings

- UV reflection coatings

- Infrared reflection coatings

- ATOX resistant coating

- Specialized coatings to manage thruster erosion

Mechanical Properties

- Thickness: 0.050 mm to 0.50 mm / 0.002” to 0.02” Special thicknesses on request

- Tolerancing: LxW ± 0.05 mm / 0.002”

- Surface Finish: As drawn to: MIL-PRF-13830B, 80/50 scratch dig

- Parallelism: 0.05 mm per 20 mm

- Perpendicularity: 90º ± 0º 30’

- Coating: Uncoated area, masked by coating tooling, shall not exceed 1% of the total coverglass area

- Edge Quality: Chemically etched for strength enhancement

- Toughening: CMX and CMG glass can be chemically toughened if required

- Humidity Resistance: 98% ± 2% relative humidity for 72 hours @ 50ºC ± 20ºC

- Adhesion: Using cellulose tape to MIL-M-13508

- Abrasion: 20 strokes with 6 mm pencil type eraser to MIL-E-12397 loaded to 10N

- Radiation Resistance: UV exposure, electron, low energy proton, high energy proton - please refer to relevant specifications

- Thermal Cycling: Details on request

Glass Options

- CMX

- CMG

- CMO

Coating Options

- Single layer Anti-reflection coatings

- 多层Anti-reflection coatings

- Conductive Anti-reflection coatings

- UV reflection coatings

- Infrared reflection coatings

- ATOX resistant coating

- Specialized coatings to manage thruster erosion

Mechanical Properties

- Thickness: 0.050 mm to 0.50 mm / 0.002” to 0.02” Special thicknesses on request

- Tolerancing: LxW ± 0.05 mm / 0.002”

- Surface Finish: As drawn to: MIL-PRF-13830B, 80/50 scratch dig

- Parallelism: 0.05 mm per 20 mm

- Perpendicularity: 90º ± 0º 30’

- Coating: Uncoated area, masked by coating tooling, shall not exceed 1% of the total coverglass area

- Edge Quality: Chemically etched for strength enhancement

- Toughening: CMX and CMG glass can be chemically toughened if required

- Humidity Resistance: 98% ± 2% relative humidity for 72 hours @ 50ºC ± 20ºC

- Adhesion: Using cellulose tape to MIL-M-13508

- Abrasion: 20 strokes with 6 mm pencil type eraser to MIL-E-12397 loaded to 10N

- Radiation Resistance: UV exposure, electron, low energy proton, high energy proton - please refer to relevant specifications

- Thermal Cycling: Details on request